Recommended Minimum Plate Thickness Of Steel And Aluminum For ARC Stud Welding.

| Base Diameter

Of Stud in inches(mm) |

Steel | Aluminum | ||

| Without Backup | Without Backup | With Backup | ||

| inch/mm | Std. Gage | inch/mm | inch/mm | |

| 3/16 (4.8mm) | 0.036/0.91 | 20 | 0.125/3.20 | 0.125/3.20 |

| 1/4 (6.4mm) | 0.048/1.21 | 18 | 0.125/3.20 | 0.125/3.20 |

| 5/16 (7.9mm) | 0.060/1.52 | 16 | 0.187/4.70 | 0.125/3.20 |

| 3/8 (9.5mm) | 0.075/1.90 | 14 | 0.187/4.70 | 0.187/4.70 |

| 1/2 (12.7mm) | 0.120/3.04 | 13 | 0.250/6.40 | 0.187/4.70 |

| 5/8 (15.9mm) | 0.148/3.80 | 11 | 0.250/6.40 | 0.250/6.40 |

| 3/4 (19.1mm) | 0.187/4.70 | – | – | – |

| 7/8 (22.2mm) | 0.250/6.40 | – | – | – |

Accommodating The Weld Fillet On ARC Weld Studs

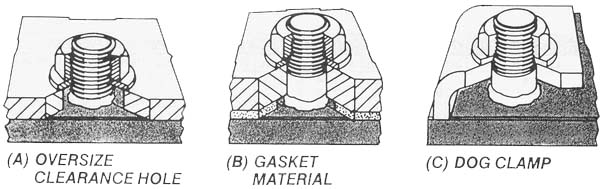

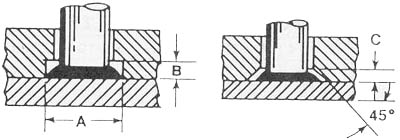

When a stud is end-welded, a weld fillet forms around its base with the dimensions being closely controlled by the design of the ferrule being used. Since the diameter of the weld fillet is generally larger than the diameter of the stud, some consideration is required in the design of mating parts. Counter bore and counter sink methods are commonly used. Dimensions will vary with different stud and ferrule types. Additional methods of accommodating weld fillets include oversize clearance holes, use of a gasket material around the fillet or use of a dog-type construction.

| Stud Size | Counterbore | 90° Countersink | |

| A | B | C | |

| inch/mm | inch/mm | inch/mm | |

| 1/4 (6.4mm) | 0.437/11.1 | 0.125/3.2 | 0.125/3.2 |

| 5/16 (7.9mm) | 0.500/12.7 | 0.125/3.2 | 0.125/3.2 |

| 3/8 (9.5mm) | 0.593/15.1 | 0.125/3.2 | 0.125/3.2 |

| 1/2 (12.7mm) | 0.750/19.1 | 0.187/4.7 | 0.187/4.7 |

| 5/8 (15.9mm) | 0.875/22.2 | 0.218/5.5 | 0.187/4.7 |

| 3/4 (19.1mm) | 1.125/28.6 | 0.312/7.9 | 0.187/4.7 |

Several Methods of Fillet Accommodation:

|

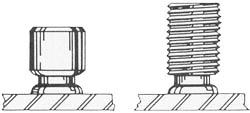

If An Oversized Fillet Does Not Meet An Application:Welded Studs with a reduced base are available so that the weld fillet does not exceed the maximum diameter of the fastener. This design is not recommended if full fastener strength is important. |