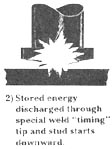

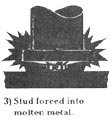

1.) Stud Against The Work  2.) Stored energy discharged through special weld tip and starts moving downward.  3.) Stud is forced into the molten metal.  4.) The metal solidifies and the weld is completed in milliseconds. |

Capacitor Discharge Stud Welding ProcessCapacitor Discharge (CD) Stud Welding involves the same basic principles and metallurgical aspects as any other arc welding procedure. When the weld gun is activated a special precision weld tip initiates a controlled electric arc from the welder capacitor bank which melts the end of the stud and a portion of the base metal. The stud is held in place as the molten metal solidifies instantly accomplishing a high-quality fusion weld. CD Stud Welding is generally used to weld smaller diameter studs to thin base metals, especially where reverse side marking is not permissible. Since the entire weld cycle is completed in milliseconds, welds can be made with a much thinner material without pronounced distortion, burn-through or reverse side discoloration. As long as one end of the stud is designed for CD welding, CD studs can be manufactured in almost any shape. CD Stud Welding is compatible with just about any weldable material and permits the welding of dissimilar metals. CD Stud welding is the process of choice when:

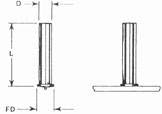

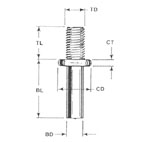

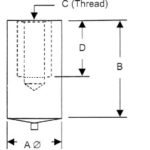

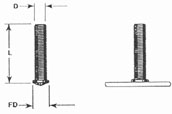

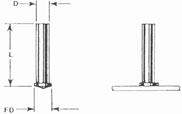

CD Stud/Base Metal Combination Welding Capabilities Chart CD Stud Load/Torque Strength Charts (Imperial Unit of Measurement) CD Stud Load/Torque Strength Charts (Metric Unit of Measurement) CD Stud Weld Inspection (Visual) CD Stud Types*: (Not all available styles shown, see list below for other styles of CD studs not pictured.)

*Metric Studs are also available in all stud types Other Types of CD Studs (Not Shown)

|