ARC Stud Welding Process

ARC Stud welding involves the same basic principles and metallurgical aspects as many other arc welding procedure. The weld gun lifts the stud a short distance from the base metal and initiates a controlled electric arc from the power source which melts the end of the stud and a portion of the base metal. The ceramic ferrule contains the molten metal into which the stud is thrust automatically and a high quality fusion weld is accomplished.

ARC Stud Welding is generally used to weld larger diameter studs to thick base metals. ARC studs may be almost any shape and there are literally hundreds, however they must have one end of the stud designed for ARC welding, and must be made of weldable materials. Mild steel, stainless steel, and aluminum are applicable materials for ARC stud welding.

ARC Stud welding is the process of choice when:

- The material is dirty, scaly or oily.

- The application is structural.

- High strength is a requirement.

- Fastener diameters are 3/16″ or larger.

- Higher carbon steels are required.

General ARC Stud Welding Information

ARC Stud Location Template & Bushing Design (Fixturing)

Minimum Plate Thickness/Accommodating Weld Fillet

ARC Stud Load/Torque Strength Charts

ARC Stud Load/Torque Strength Charts (Metric Studs)

ARC Stud Visual Weld Inspection

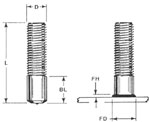

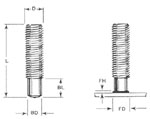

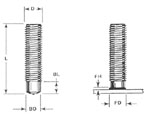

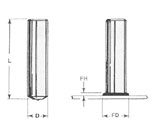

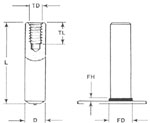

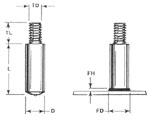

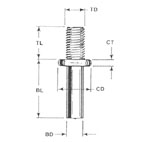

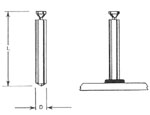

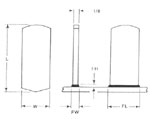

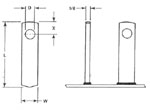

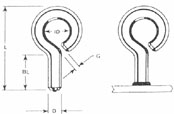

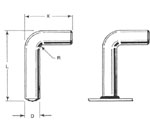

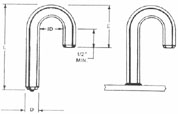

ARC Stud Types*:

*Metric Studs are also available, MES standard metrics are in the reduced base style, although any stud type can be manufactured with metric dimensions.